Production and Characteristics of Football Turf

Artificial turf has become the first choice for football field grass because of its strong vitality and long service life. It is the most important material for outdoor and indoor football turf fields and landscapes. Its production process has undergone strict production processes and meticulous workmanship. The production of football field grass involves a process that requires expertise, which requires certain special points and conditions to be fulfilled. In order to make professional football turf courts beautiful and practical, the production process of synthetic sports turf must also be meticulous.

What Are the Factors Affecting the Quality of Artificial Football Turf?

Football field grass is basically woven with special yarns on a special carpet that looks like real grass and stays green no matter the season, making it easier to maintain than real grass. The installation of artificial football turf has different characteristics according to its purpose and can be used for sports, landscaping, and other purposes.

The quality of artificial football turf is influenced by a range of factors that together determine its performance, safety, and longevity. Understanding these factors is critical to choosing the best turf for your sports facility. The following is an overview of the key factors affecting the quality of artificial football turf:

Fiber Quality and Material: The type of synthetic fiber used in a turf plays a key role in its overall quality. High-quality fibers are durable and resilient to withstand frequent use. Factors such as fiber thickness, shape, and composition affect attributes such as softness, ball response, and player comfort.

Filling Material: Filling materials such as rubber granules or sand help improve the shock absorption, traction, and overall playability of the turf. The type and quality of infill affect how the turf interacts with players and balls. Correct padding distribution is critical for consistent performance.

Base Construction: The base provides stability and drainage to the lawn. A well-constructed base and proper drainage prevent standing water that can affect playability and durability. The quality of the base directly affects the overall performance and longevity of the turf.

Backing System: The backing system secures the synthetic fibers to the base layer. The strong and durable backing keeps the fibers securely in place, maintaining the integrity of the playing surface. The quality of the backing system affects the abrasion resistance of the turf.

Installation Expertise: Proper installation is critical to the long-term quality of artificial football turf. Skillful installation ensures even fill distribution, accurate fiber placement, and optimum drainage. Improper installation can result in uneven surfaces, inconsistent playability, and reduced durability.

Drainage Capacity: Effective drainage is essential to prevent surface water accumulation. Poor drainage can lead to water accumulation in the field, affecting play and safety. High-quality artificial soccer turf includes a drainage system that efficiently moves water away from the surface.

Anti-UV: Outdoor artificial football turf is exposed to sunlight, which will cause fading and deterioration over time. High-quality turf is treated to resist UV radiation and retain its color and appearance even after prolonged exposure to sunlight.

Routine Maintenance: The quality and consistency of maintenance practices significantly impact the lifespan and performance of artificial soccer turf. Regular cleaning, grooming, and filling are necessary to keep your lawn in top condition.

Intensity of Use: Frequency and intensity of use will affect how quickly your turf will show signs of wear. High-traffic areas, such as goals and central areas, are more prone to wear and tear and may require additional maintenance.

Climate and Weather Conditions: Extreme weather conditions, such as heavy rain or extreme heat, can affect the performance and durability of artificial football turf. A quality lawn should be designed to withstand a variety of weather conditions without deterioration.

Artificial Football Turf Production Process

The production of football turf involves several complex steps to create a surface that is both durable and suitable for players. Here is an overview of some of the key stages in the manufacture of football turf by SYSTURF:

1.When we started to make artificial turf, we used polypropylene + polyethylene as the base material. They are then mixed with green granules for a lush green color, and UV stabilizers are added to ensure the fibers can withstand years of sun and heat without degrading. Once the ingredients are thoroughly mixed to ensure homogeneity and color consistency, they are transferred to extrusion.

2.During the extrusion process, we utilize advanced machinery to melt and shape these pellets into green bodies. Rollers stretch them, making the synthetic filaments as fine as ordinary grass. The strands are then cooled and solidified. During this process, the synthetic fibers become elastic and form the ideal structure for synthetic turf.

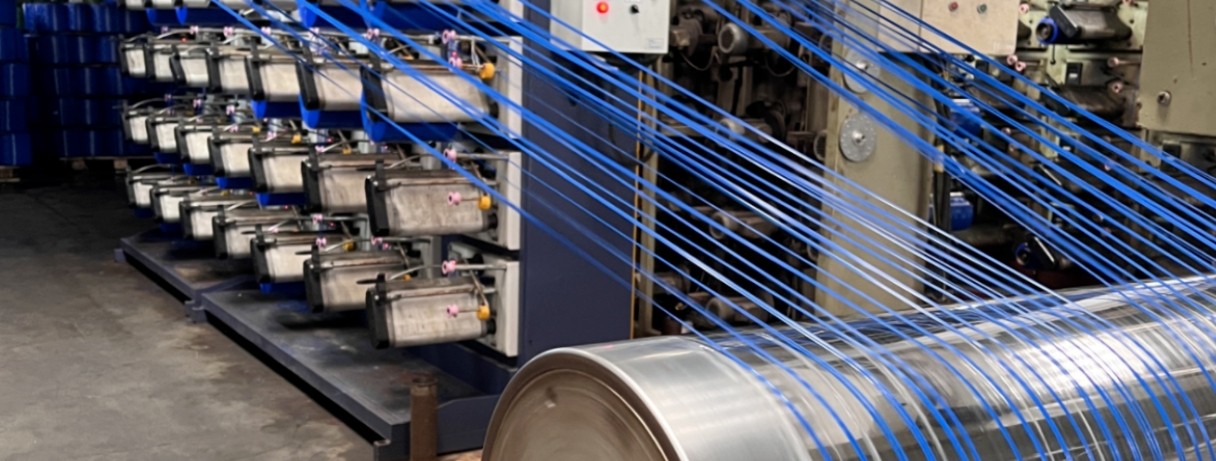

3.Thereafter, the spool winds up the fiber until it is full. Several spools are then unwound at a time, and their fibers are brought together to form a composite multi-ply yarn. The yarn is then wound together with large spools.

4.Next, the multi-ply synthetic thread goes down the production line to a tufting machine, which is essentially a giant sewing machine. The rayon is then pierced through the fabric backing using the needles on the tufting machine. The machine can sew hundreds of stitches per minute. Beneath these stitches, a knife cuts the synthetic yarn, giving it the shape of a blade of grass.

5.Once inspectors have ensured that the synthetic grass fibers are even, they are sent to coating rollers on the machine, which apply the adhesive coating to the backing of the synthetic turf. This fully bonds the synthetic grass blades into the backing.

6.Once the coating is applied, it is cured in a temperature-controlled dryer. Then, once the coating dries, the artificial turf is burnt with holes by hot needles, which makes the artificial turf permeable and quick-draining.

7.When it's time to install artificial turf, lay down the rubber base and add grass on top of it. The sand is then distributed throughout the artificial turf to add weight and help the grass blades stand upright for the best look.

8.Throughout the production process, we strictly implement quality control measures. Each stage is closely monitored to ensure the material is installed correctly, the weave is consistent and the filling is evenly distributed. This attention to detail ensures that the final product meets the highest standards of quality and safety.

9.SYSTURF's artificial soccer turf undergoes a comprehensive testing and certification process before it can be put into use. These tests evaluate various factors such as shock absorption, ball bounce and player traction. Turf must meet strict industry standards to ensure a safe and optimal playing surface.

10.SYSTURF prioritizes sustainability in its production process. This includes using recycled materials for padding and backing systems, and implementing environmentally friendly manufacturing practices. By reducing environmental impact, football turf production is in line with broader efforts to create more sustainable sports facilities.

How to Install an Artificial Turf Soccer Field?

The construction of beautiful, functional and attractive artificial turf is based on multiple stages. You need to take care of the companies you work with. SYSTURF provides high-quality products and services to customers in more than 40 countries and regions around the world, covering Europe/North America/Latin America/Middle East/Asia, Africa and other places. Basically, SYSTURF's synthetic turf models are woven on a special base fabric using synthetic green primary fibers or monofilament yarns, and cut to a certain pile length. The types of yarns used to weave artificial turf are divided into monofilaments and fibres.

Fibrillated threads are standard synthetic threads that are more convenient and last for years. Monofilament yarns, on the other hand, are a new generation of yarns, also available in vertebrate models. They provide a more realistic and vivid look. The stages of professional artificial turf installation can be listed as follows;

The grass yarn is carefully woven in the desired range of lengths and thicknesses in the tufting machine, unlike ordinary carpet weaving machines. After the grass is removed from the tufting machine and left in pristine condition, it is transferred to the latex coating unit. Latex material is the name of a liquid obtained by a special method from the trunk of rubber trees that grow in tropical regions. By turning this liquid into blocks in a special way, extremely flexible and durable materials can be produced. When the artificial turf comes out of the oven, it is ready to use. By this period, the production of artificial turf is over. After finishing the necessary finishing and maintenance, it can be placed on the area to be used according to the preference.

What Are the General Characteristics of Football Turf?

Artificial grass is very durable and high-performance grass compared to natural grass. By maintaining your artificial football turf regularly, you can always achieve a vibrant green look. Synthetic grass is long-lasting and affordable in terms of the cost of installing artificial turf football pitches; since artificial grass is produced using durable materials, it can provide a long lifespan after the turf is installed. With proper maintenance, artificial turf can retain its first-day quality for years. As would be expected from a natural lawn, there is no such definition of time.

It does not require maintenance such as fertilization, mowing, irrigation, etc., which has a huge advantage in terms of artificial football turf installation costs. This type of maintenance is the most difficult part of natural lawns to deal with. With artificial turf, however, you don't need to do such maintenance, and you can estimate the cost of a soccer turf at a much more affordable cost. The pile length of the fake grass can be arranged within the desired range to best suit the area of use. This way, you can see the most accurate grass growth you need.

Buying Football Artificial Turf From SYSTURF

As a professional custom artificial turf manufacturer, SYSTURF has a professional R&D team, develops new products regularly, and can also customize products according to needs. If you need to order artificial turf, please contact us.

We have 24-hour dedicated personnel to answer online questions about product selection and customization, supporting facilities, sports field design, etc., as well as after-sales questions such as pavement construction guidelines, lawn aging, maintenance and replacement.